Evaporative cooling is an excellent alternative to the use of disposable water in heat dissipation in industrial plants. In addition to cost and resource savings, much lower temperatures can be achieved with evaporative cooling than with air cooling, resulting in considerable savings in energy consumption.

All these advantages can be summarised as improved energy efficiency, better air quality, no carbon emissions and lower initial purchase, installation and maintenance costs.

The various types of adiabatic machines we build cool water or other fluids (glycol, refrigerant gas) by evaporating a small amount of water relative to the mass of fluid they handle.

Each type of machine differs from the others in the way it exploits this principle. Let us look at them in detail:

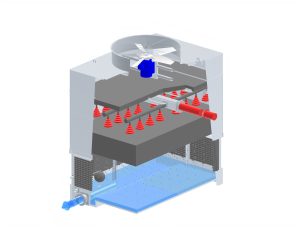

Open circuit tower

In open circuit towers, hot water from the utilities is conveyed into the tower where it is sprayed, through large diameter nozzles, onto a honeycomb pack (exchange pack). The function of the exchange pack is to drastically increase the exchange surface area of the heat contained in the water with the air it encounters. The flow of air is achieved through the use of fans that can be placed in the upper part (forced operation) or in the lower part of the tower (induced operation).

The water thus cooled is then collected in a basin placed under the machine (integrated into the machine) or simply in concrete or steel containers (remote basin). From the basin, the water is drawn off via recirculation pumps and sent to the consumers, thus forming a circuit (open type).

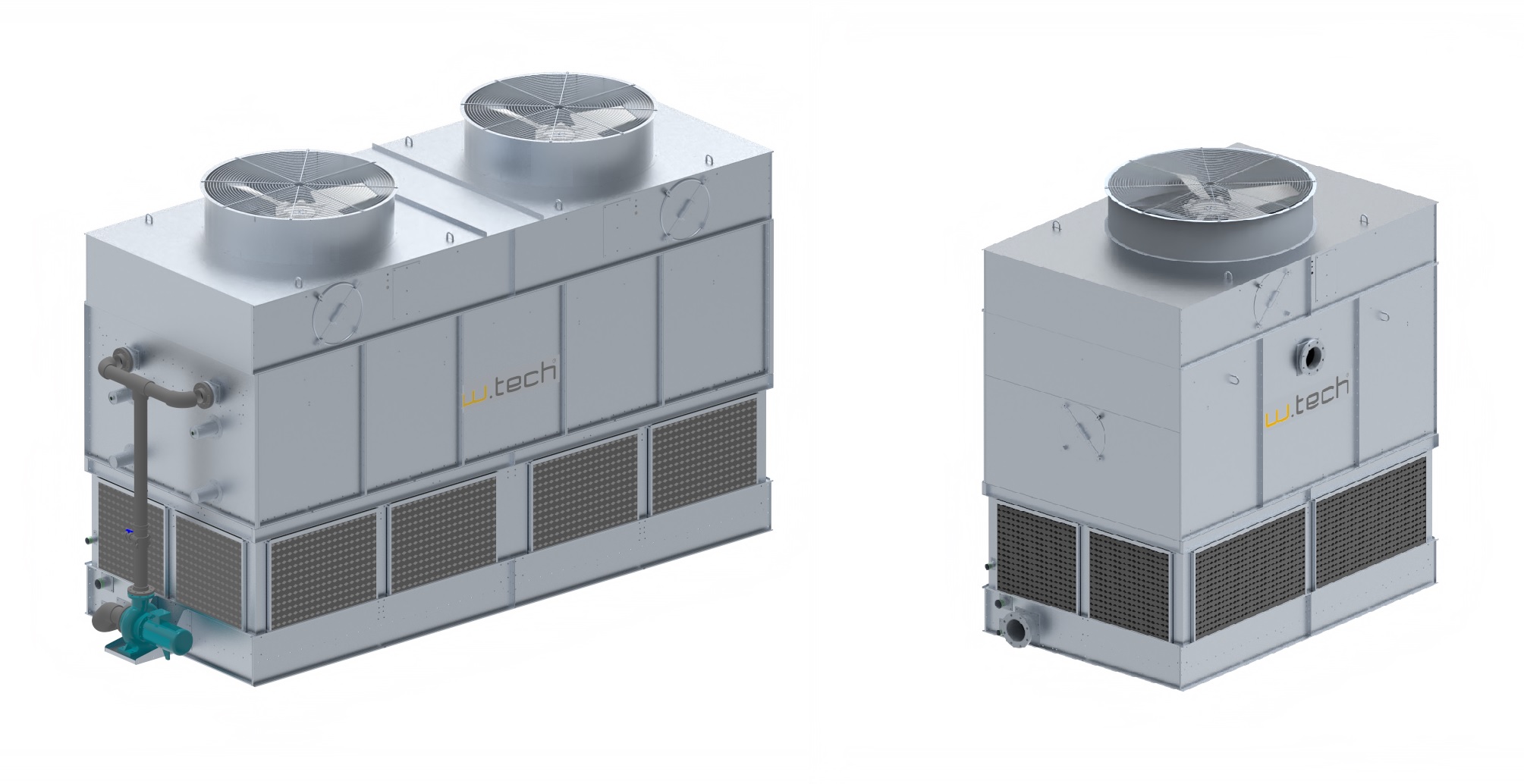

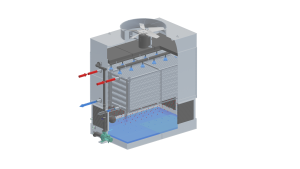

Closed Circuit Tower

Although the operation is similar to an open tower, in closed-circuit towers we find a heat exchanger (coil) in place of the exchange pack. Inside the exchanger, hot water (or glycol) from the system’s utilities is conveyed (primary circuit) while outside, water drawn from the reservoir is recirculated (secondary circuit). It is clear, therefore, that the two fluids (or the two circuits) are not in contact with each other and so possible impurities from the secondary circuit will never contaminate the users of the primary circuit. This aspect is very important precisely where the conditions of the installation site are not optimal (sand, various impurities, trees or vegetation nearby).

Evaporative condenser

The evaporative condenser is to all intents and purposes a closed circuit machine, but instead of water (or glycol) in the primary circuit, we have a refrigerant gas (freon, ammonia, etc.). In this case, the hot gas from the compressor enters the coil in a gaseous state and is condensed by the water in the secondary circuit and the air current generated by the fan.

Fields of use

We have seen the characteristics of the three main types of machines. These can be constructed in various ways, depending on where the fans are placed and the type of fans used. These differences are imposed by various factors, among which we can mainly identify energy efficiency, noise level, and restrictive conditions on dimensions. In addition, our production program includes a considerable number of options and accessories to accompany the machine, which are listed in the options list that can be downloaded directly from the site in the download section.

Usual machine use

Open or closed towers:

– Power generation and cogeneration plants

– Metallurgical installations

– Chemical-pharmaceutical plants

– Food and concentration plants

– General industrial/air-conditioning and refrigeration plants

– Plants for moulding, plastic blowing, paper mills

Evaporative condensers:

– Industrial refrigeration systems

Which machine is best suited to your needs?