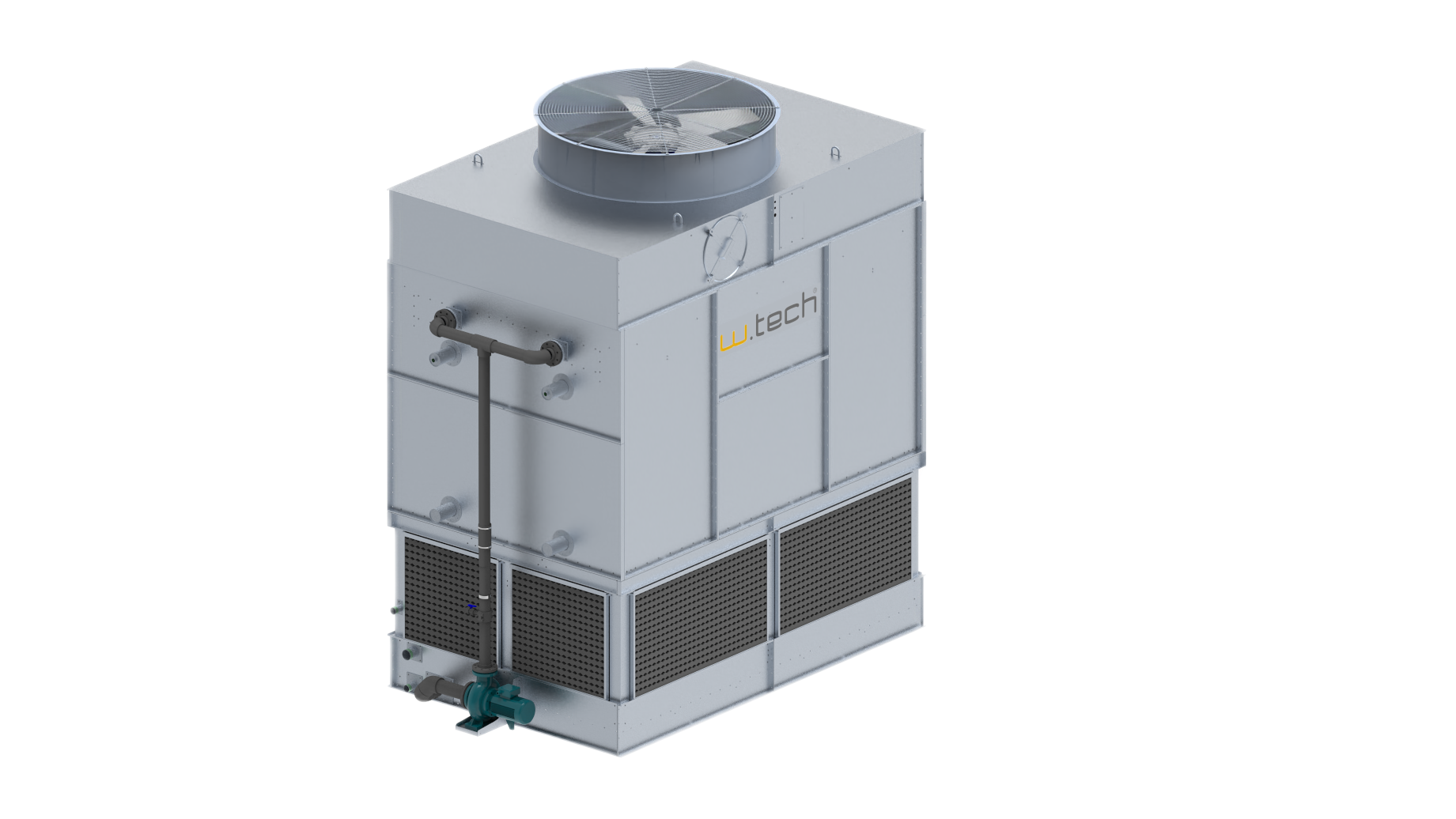

La versione assiale dei condensatori evaporativi è simile ai raffreddatori evaporativi, con batteria di scambio termico e pompa di ricircolo. La batteria di scambio termico può essere realizzata in acciaio inossidabile AISI 304 e AISI 316L. Tutti i condensatori evaporativi W-tech sono certificati PED.

Assemblaggio

Factory assembled

Capacità

195 – 2171 kW

Certificazioni

2006/42/CE; (Direttiva Macchine ); Direttiva PED 2014/68/UE

2014/30/UE; (Compatibilità Elettromagnetica)

2014/35/UE; ( Bassa Tensione)

UNI EN ISO 12100:2010 (Sicurezza del macchinario)

ISO 9001:2015; Marcatura CE

Configurazione

CounterFlow

Disponibilità

All over the world

EVAPORATIVE CONDENSERS

An evaporative condenser condenses a refrigerant gas from a gaseous state to a liquid. By traveling along a coil from top to bottom sprayed with water with air in countercurrent, the refrigerant gas condenses and changes phase. Medium-large capacity refrigeration systems are usually water-condensed, especially if they use ammonia as a refrigerant. It is essentially a hybrid between an air-cooled condenser and a water-cooled condenser that uses heat rejection principles to follow an evaporative process.

The choice of a water-cooled condensing unit such as W-tech evaporative condensers over air-cooled units is simple:

Consistency of performance

during the year thanks to lower condensation temperatures

Greater thermal efficiency

during the winter/summer months

Optimal performance

thanks to the use of falling recirculating water with counter-current air

Lower electrical absorption

compared to an air unit

SCHEDA PRODOTTO

CARATTERISTICHE COSTRUTTIVE

W-Tech CAA series, evaporative condensers with axial fans, are manufactured and assembled in accordance to our Quality System certified by ISO 9001.

MAGNELIS

All our machines are built as standard in Magnelis®, it is an eco-sustainable alloy made up of 93.5% zinc, 3.5% aluminum and 3% magnesium. The percentage of magnesium allows the self-repair process after cutting and punching operations and protects deformed surfaces. Another characteristic is the corrosion resistance, superior even in environments rich in chloride and ammonia. The maximum workability and greater resistance, compared to other materials, allows the use of a smaller quantity of metal coating and therefore a greater lightness of the machines.

STRUTTURA & ASSEMBLAGGIO

The standard unit is built with Magnelis® (steel, zinc, aluminium, magnesium) ZM310 type sheet metal panels to ensure maximum surface protection empirically comparable to a galvanized sheet metal with over 1000 g/m2 of zinc. The individual panels, following the cutting and folding phase, are assembled with AISI 304 (A2-70) or on request AISI 316 (A4-80) stainless steel small parts and highly adhesive butyl mastic gasket reinforced with polyester mesh inside to guarantee great shape stability and resistance to temperature variations. No welding is required in the various stages of assembly of the structure (self-supporting). The color of the sheet metal type Magnelis® is RAL 9006.

GRIGLIE PRESA ARIA

Louvers are in PVC with special dual flow design in order to eliminate the sun light into the water basin, possible residue/leafage or accidental water leakage. Positioned on the four sides of the unit, louvers can be completely removed to allow an easy access to the basin during maintenance.

BACINO RACCOLTA ACQUA

The basin section is built with a thick Magnelis® ZM310 sheet metal structure and is equipped with of removable anti-cavitation type filter in AISI 304L (to protect the primary circuit pump) and water make-up valve with brass/stainless steel body and floating sphere in stainless steel or polypropylene. The configuration of the basin is such as to allow the reduction of the volume of water and therefore a lower weight during operation. The surface of the basin is inclined to allow complete drainage and emptying in case of maintenance, avoiding water stagnation and preventing bacteriological development. All machine connections are made of galvanized steel (AISI 304L on request).

SERPENTINA DI SCAMBIO TERMICO

La serpentina di scambio termico standard è realizzata in tubi lisci (in opzione alettati) di acciaio al carbonio (AISI 304L su richiesta) di opportuni diametro e spessore e piegata seguendo la nostra geometria proprietaria. Il tutto viene zincato a bagno caldo in accordo alla norma UNI EN ISO 1461:2009 per garantire una perfetta tenuta alla corrosione. Successivamente la serpentina viene collaudata in conformità alla normativa PED-CE.

Le macchine vengono fornite con la serpentina pre-caricata con azoto alla pressione di 3 bar.

SISTEMA DISTRIBUZIONE ACQUA

The water is uniformly distributed by a piping system inside the machine made of PVC with a Magnelis® sheet metal distribution box >. The spray nozzles are of the non-clogging type, of medium and large diameter, in ABS and easily replaceable in case of maintenance.

SISTEMA VENTILANTE

(MOTORI + VENTILATORI)

I ventilatori assiali sono realizzati con pale in polipropilene rinforzato con fibra di vetro (PPG) ad alta efficienza, mozzo in alluminio, bussola e bulloneria in acciaio zincato. La rete di protezione del ventilatore è in acciaio zincato. I motori, classe di efficienza IE3, con protezione meccanica IP56 tropicalizzati, studiati appositamente per il funzionamento in atmosfera umida, classe di isolamento F, servizio continuo S1, forma V6 e scarico condensa automatico, sono calettati direttamente ai ventilatori assiali (accoppiamento diretto). I motori elettrici subiscono un ciclo di verniciatura in classe C5 per garantire la massima protezione contro corrosione e umidità. I motori sono idonei ad essere accoppiati a variatori di frequenza (VSD-Inverter) 30-50Hz.

I motori sono in accordo alla normativa CE 2019/1781.

Il cavo di collegamento uscente direttamente dalla carcassa del motore elettrico, è portato al di fuori della struttura e cablato direttamente ai morsetti in apposita scatola di derivazione IP56.

SEPARATORI DI GOCCE

Drift eliminators are made in PVC (PP on request) and divided in various sections to facilitate their removal in case of replacement or inspection of ventilation and water distribution system. The used drift eliminators allow a passage of drops equal to 0.001% of the droplets present at the entrance, removing water loss, potential aerosols drift that might contain Legionella bacteria.

TEST

All components are supplied assembled. Each unit, before delivery, is subjected to hydraulic testing, to ensure that there are no water leaks in the tank, and electrical to check that the electric motors have an absorption in line with the plate data.

CATALOGHI E DATI TECNICI

Catalog list.

CERTIFICAZIONI

ENTERS OUR WORLD

W-TECH

BOOK A DEMO

Contact our technicians for a free quote or information request!