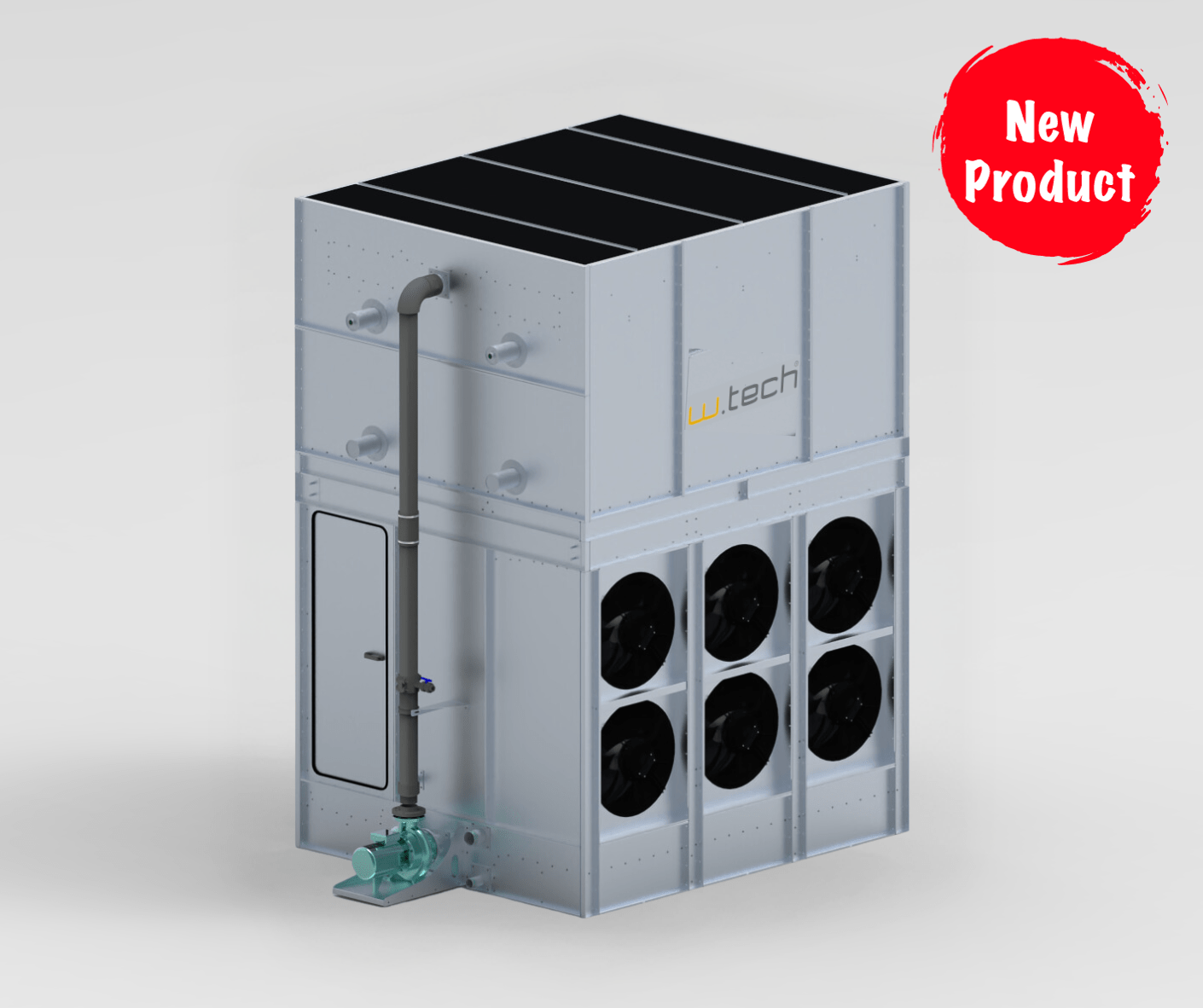

This innovative evaporative condenser, with preassembled axial EC fans, guarantees better performances and minimum maintenance. Overall running costs are much lower, as are installation and operating costs compared to older generation capacitors. This innovative evaporative condenser represents a sustainable solution for industrial refrigeration and other industrial process applications.

Assembly

Factory assembled

Capacity

–

Certifications

2006/42/EC; (Machinery Directive)

2014/30/EU; (Electromagnetic Compatibility)

2014/35/EU; (Low Voltage)

UNI EN ISO 12100:2010 (Machinery safety)

ISO 9001:2015; CE marking

Configuration

CounterFlow

Availability

All over the world

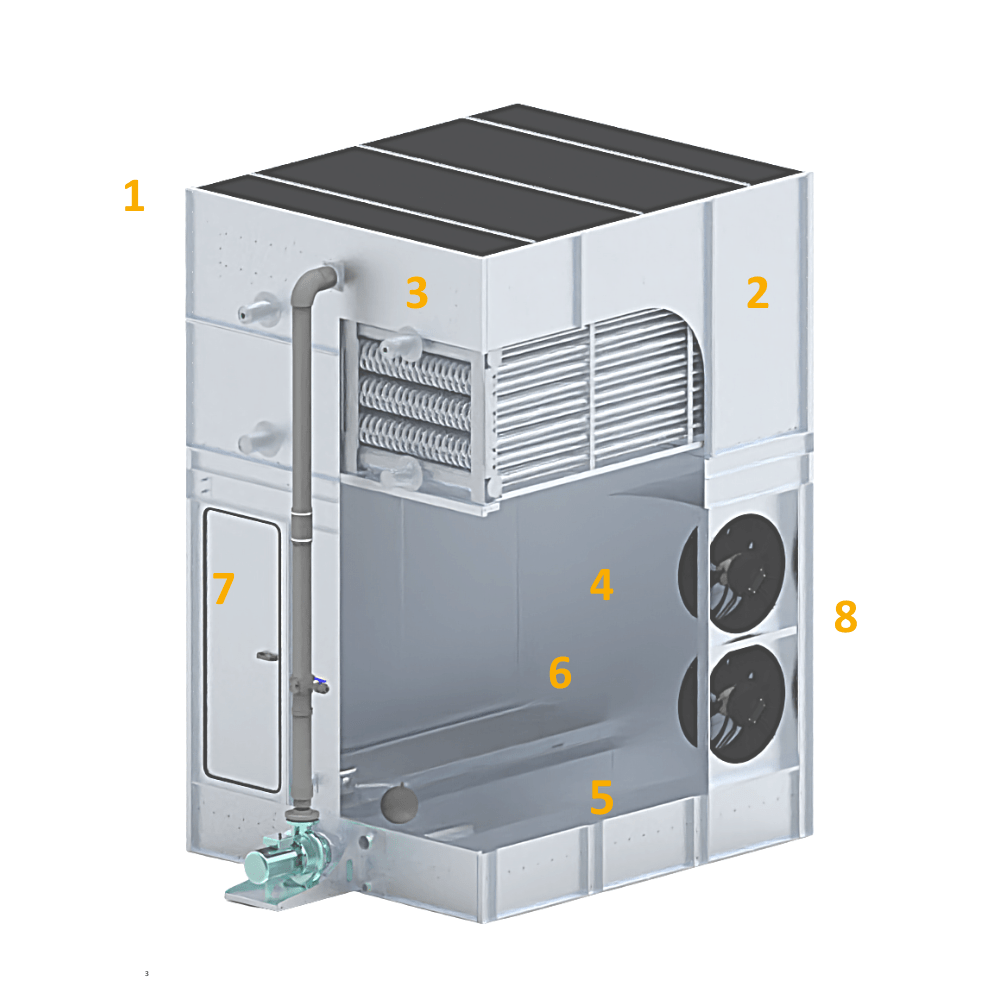

1. Easy to install

The CAPX has a very easy-to-install format, which allows our customers to reduce installation costs and make the installation on time.

2. Magnelis Structure

Magnelis has excellent corrosion resistance: three times better than galvanised steel (based on salt spray tests). The self-healing effect guarantees excellent edge protection.

3. Simple maintenance

Thanks to the arrangement and management of the EC vents, they can be replaced more quickly; the spray nozzles can also be removed without the aid of any tools, for fast cleaning and easy maintenance.

4. EC motor

The CAPX is equipped with EC motors controlled by an on-board electronic board and a control panel with a specific electronic controller for refrigeration units. This allows greater control and efficiency, adapting to the conditions of the working environment.

5. Basin

A new design reduces the tank volume by at least 25% and eliminates any areas of stagnant water. With savings on chemicals and water, up to 30%.

6. Internal Walkway

Technicians can stay dry while safely inspecting the tank (with the unit off), thanks to the sturdy internal walkway.

7. More comfortable access

The door opens to a span of 160×60 cm, which makes it easier and safer to enter the machine.

8. Ventilating group

This ventilation system is based on the independent operation of 2 fan banks and minimizes energy costs by reducing the period of activity of the fan banks in periods of low load or low external temperature.

EVAPORATIVE CONDENSERS

An evaporative condenser condenses a refrigerant gas from a gaseous state to a liquid. By traveling along a coil from top to bottom sprayed with water with air in countercurrent, the refrigerant gas condenses and changes phase. Medium-large capacity refrigeration systems are usually water-condensed, especially if they use ammonia as a refrigerant. It is essentially a hybrid between an air-cooled condenser and a water-cooled condenser that uses heat rejection principles to follow an evaporative process.

The choice of a water-cooled condensing unit such as W-tech evaporative condensers over air-cooled units is simple:

Consistency of performance

during the year thanks to lower condensation temperatures

Greater thermal efficiency

during the winter/summer months

Optimal performance

thanks to the use of falling recirculating water with counter-current air

Lower electrical absorption

compared to an air unit

PRODUCT DATA SHEET

CONSTRUCTION FEATURES

The CAPX type machines, evaporative coolers with EC axial fans, are built and assembled in accordance with our ISO 9001 certified quality system.

STRUCTURE & ASSEMBLY

The standard unit is built with Magnelis® (steel, zinc, aluminium, magnesium) ZM310 type sheet metal panels to ensure maximum surface protection empirically comparable to a galvanized sheet metal with over 1000 g/m2 of zinc. The individual panels, following the cutting and folding phase, are assembled with AISI 304 (A2-70) or on request AISI 316 (A4-80) stainless steel small parts and highly adhesive butyl mastic gasket reinforced with polyester mesh inside to guarantee great shape stability and resistance to temperature variations. No welding is required in the various stages of assembly of the structure (self-supporting). The color of the sheet metal type Magnelis® is RAL 9006.

WATER COLLECTION BASIN

The basin section is built with thick Magnelis® ZM310 sheet metal paneling and is equipped with removable anti-cavitation filter in AISI 304L (to protect the secondary circuit pump) and water make-up valve with brass/stainless steel body and stainless steel or polypropylene floating ball. All machine connections are made of galvanized steel (AISI 304L on request). The water recirculation pump is housed outside the basin structure, with a cast iron body and IP54 motor protection rating.

THERMAL EXCHANGE COIL

The standard heat exchange coil is made of smooth (optionally finned) carbon steel tubes (AISI 304L on request) of suitable diameter and thickness and bent following our proprietary geometry. Everything is hot-dipped galvanized in accordance with the UNI EN ISO 1461:2009 standard to guarantee perfect resistance to corrosion. Subsequently the coil is tested in compliance with the PED-CE regulation.

The machines are supplied with the coil pre-charged with nitrogen at a pressure of 3 bar.

WATER DISTRIBUTION SYSTEM

The water is uniformly distributed by a piping system inside the machine made of PVC with a Magnelis® sheet metal distribution box. The spray nozzles are of the non-clogging type, of medium and large diameter, in ABS and easily replaceable in case of maintenance.

The pipes that connect the recirculation pump with the internal ramp are made of PVC, easily removable for possible cleaning of the circuit, in accordance with the latest health provisions (anti-legionella).

VENTILATION SYSTEM

(MOTORS + FANS)

The fan part is located along one side of the basin section, on this wall are fixed the 2 banks of electric fans complete with diffusers and protection nets. The axial fan is made with high-efficiency and low-noise sickle-shaped aluminium blades. The fan protection mesh will be made of painted steel.

The EC axial fans with bi-frequency motor and variable speed are adjustable from 0 to 100% with external signal, while high efficiency due to permanent magnets and electronic control make it compliant with the ERP Directive. The motors comply with EU regulation 2019/1781. The power supply, control, regulation and alarm terminals are enclosed within the terminal box of the electric motor.

DROP SEPARATOR

Drift eliminators are made in PVC (PP on request) and divided in various sections to facilitate their removal in case of replacement or inspection of ventilation and water distribution system. The used drift eliminators allow a passage of drops equal to 0.001% of the droplets present at the entrance, removing water loss, potential aerosols drift that might contain Legionella bacteria.

TEST

All components are supplied assembled. Each unit, before delivery, is subjected to hydraulic testing, to ensure that there are no water leaks in the tank, and electrical to check that the electric motors have an absorption in line with the plate data.

CATALOGS AND TECHNICAL DATA

Catalog list.

CERTIFICATIONS

ENTERS OUR WORLD

W-TECH

BOOK A DEMO

Contact our technicians for a free quote or information request!