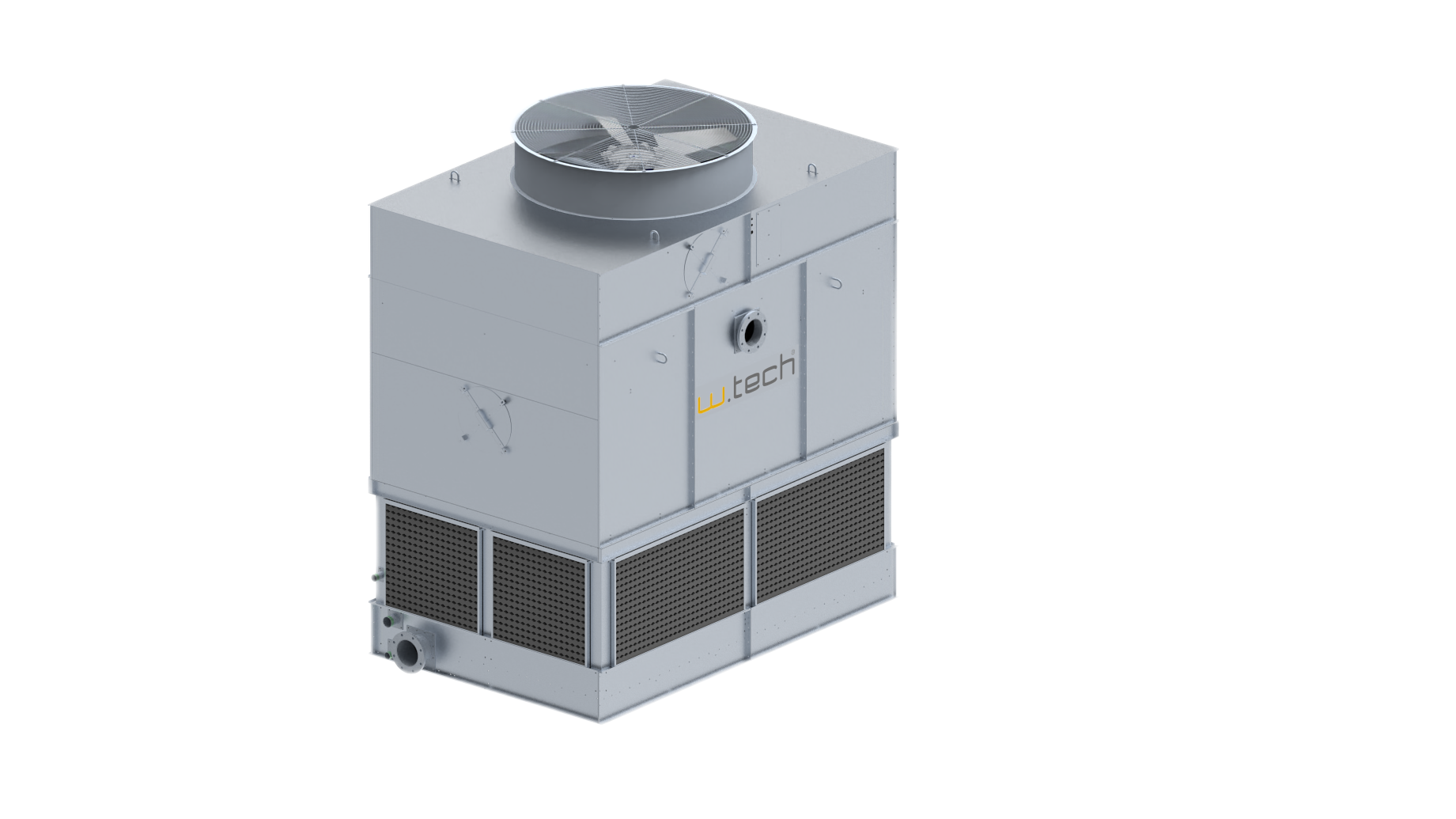

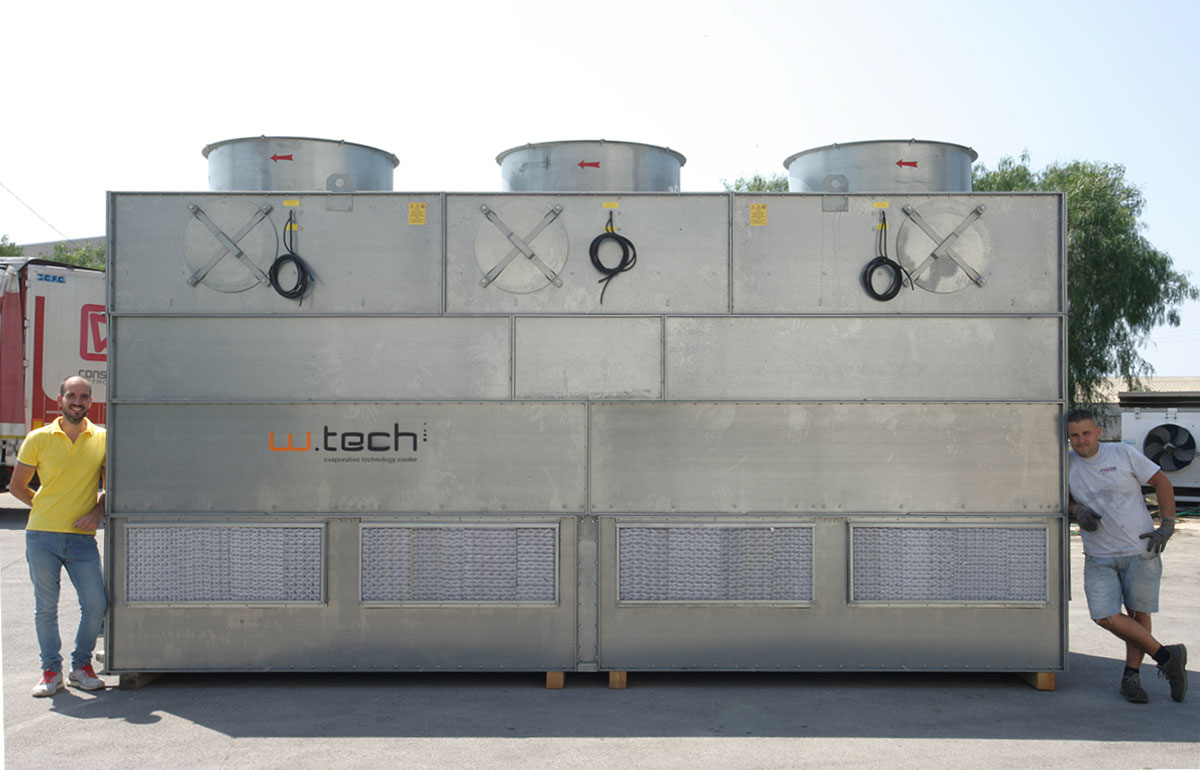

TAA axial evaporative towers are the best known machines, using axial fans on top of the machine. Our customers choose axial evaporative towers for their low power consumption and small installation space.

Assembly

Factory assembled

Capacity

50 – 7080 kW

Certifications

2006/42/EC; (Machinery Directive)

2014/30/EU; (Electromagnetic Compatibility)

2014/35/EU; ( Low Voltage)

UNI EN ISO 12100:2010 (Safety of machinery)

ISO 9001:2015; CE Marking

Configuration

CounterFlow

Availability

All over the world

THE EVAPORATIVE TOWERS

These are machines used in industrial process cooling. Wherever there is a need to cool a substantial flow of water, W-tech evaporative towers are the best solution for:

Power generation and cogeneration plants

Metallurgical plants

Chemical and pharmaceutical plants

Food processing and concentration plants

General industrial plants/air conditioning and refrigeration plants

PRODUCT SHEET

CONSTRUCTION FEATURES

TAA-type machines, open-circuit evaporative towers with axial fans, are built and assembled in accordance with our ISO 9001-certified quality system.

MAGNELIS

All our machines as standard are built in Magnelis, an eco-sustainable alloy made up of 93.5% zinc, 3.5% aluminum and 3% magnesium. The percentage of magnesium allows the self-repair process during cutting and punching operations and protect against deformations. Another characteristic of this material is resistance to corrosion, superior even in environments rich in chloride and ammonia. The maximum workability and greater resistance, compared to other processes, allows the use of a smaller amount of metal coating and therefore a greater lightness of the machines.

STRUCTURE & ASSEMBLY

Standard unit is built with alloy steel Magnelis® ZM310 (steel, zinc, aluminum, magnesium) panels to grant the maximum level of surface protection. Comparable empirically to a galvanized sheet with over 1000 g/m2 of zinc. The single panels, after the phase of cutting and folding, are assembled with AISI 304 (A2-70) on request AISI 316 (A4-80) e guarnizione in butyl mastic highly adhesive reinforced with polyester mesh inside to guarantee great shape stability and resistance to temperature variations. During the assembling of the structure, welding operations are not foreseen (self-supporting). Magnelis® sheet metal color is RAL 9006.

LOUVERS

Louvers are in PVC with special dual flow design in order to eliminate the sun light into the water basin, possible residue/leafage or accidental water leakage. Positioned on the four sides of the unit, louvers can be completely removed to allow an easy access to the basin during maintenance.

WATER BASIN

Basin section is made with heavy thick panels of Magnelis® ZM310 thick and is equipped with a removable anti-cavitation type filter AISI 304L (to protect the primary circuit pump) and water make-up valve with brass/stainless steel body and stainless steel or polypropylene floating ball. Basin configuration permits water volume reduction and a lower weight when operating. Basin surface is sloping to permit complete drainage, emptying during maintenance and preventing then the growth of bacteria. All the unit connections are in galvanized steel (AISI 304L on request).

FILLING

The fill or exchange pack is made of PVC(PP upon request) with proprietary geometry design. The filling standard is type W1300 and on request, depending on the characteristics of the water to be used it can be type W2000 or for particularly dirty water filling W2700 is available. The geometry used is such that the heat exchange surfaces between air and water are maximized.

WATER DISTRIBUTION SYSTEM

Water is uniformly distributed on the coil by pipes made in PVC and distribution system made in Magnelis®. Spray nozzles are of suitable diameter to prevent any clogging and are made in ABS and easily replaceable in case of maintenance.

VENTILATION SYSTEM

(MOTORS + FANS)

Axial fans are built with blades in high efficiency glass fiber reinforced polypropylene (PPG), aluminum hub, compass and bolts in galvanized steel. Protection fans grids are made in galvanized steel. Motors,IE3 efficiency class, with mechanical protection IP56 tropicalized, specially designed for operation in humid atmosphere, F insulation class, continue service S1, V6 form and automatic condensate drain are directly spliced to axial fans (direct coupling).

Electric motors are protected with an additional painting cycle in C5 class, against corrosion and humidity. Motors are suitable to use together with frequency inverter (VSD-Inverter) 30-50 Hz.

Electric motors are in accordance with CE 2019/1781 norm.

The connection cable coming out directly from the electric motor casing, is carried outside the structure and wired directly to the terminals in a specific IP56 junction box.

DRIFT ELIMINATORS

Drift eliminators are made in PVC (PP on request) and divided in various sections to facilitate their removal in case of replacement or inspection of ventilation and water distribution system. The used drift eliminators allow a passage of drops equal to 0.001% of the droplets present at the entrance, removing water loss, potential aerosols drift that might contain Legionella bacteria.

TEST

All components are supplied assembled. Each unit, first

of delivery, it is subjected to hydraulic testing in order to

Make sure there are no water leaks in the tank, and

electric to verify that electric motors have a

absorption in line with nameplate data.

CATALOGS AND TECHNICAL DATA

Catalog list.

CERTIFICATIONS

ENTERS OUR WORLD

W-TECH

BOOK A DEMO

Contact our technicians for a free quote or information request!