Evaporative condensers: what they are

The evaporative condenser is essentially a combination of a water-cooled condenser and an air-cooled condenser, using the principle of heat dissipation through the evaporation of water in a flow of air travelling through the condensing coil. While water-cooled condensers require a lot of water flow, evaporative condensers use a small portion of cooling water loss per unit of cooling capacity. The compact design also requires less space and offers greater cooling capacity.

The evaporative condenser system typically consists of a series of tubes carrying hot refrigerant gas. These tubes are simultaneously exposed to a spray of water and a flow of air facilitated by a fan. Some of the water flowing over the gas-filled tubes evaporates due to a combination of heating the tubes and the airflow. This evaporation is the mechanism that allows rapid cooling of the refrigerant gas, which is then pumped back, the remaining water being collected and recirculated over the condenser coils.

The condensation process

Superheated refrigerant vapour enters the condenser, where it loses heat by passing close (i.e. the thickness of a pipe wall) to a refrigerant. The refrigerant can be air, water or other fluids. The refrigerant vapour is first cooled to its saturation temperature (dependent on the vapour pressure), at which point condensation begins. While condensing in a liquid at a constant temperature, latent heat is released. Only when the condensation process is finished does the temperature of the refrigerant begin to drop again.

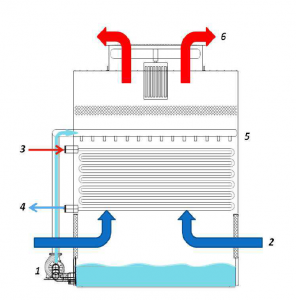

In evaporative condensers the process fluid (refrigerant gas)(3,4) is circulated in the heat exchange coil of the closed circuit system. The recirculating water (1) sprayed by the nozzles (5) above the heat exchange coil and the countercurrent air (2) drawn by the fan contribute synergistically to dissipate the heat of the process fluid through the tubes of the heat exchange coil. A part of the water evaporates by removing heat from the process fluid, being introduced into the atmosphere with the flow of air leaving the upper part of the condenser (6). The water that does not evaporate falls back into the basin and is recirculated by the condenser pump.

Evaporative advantages

- The application of evaporative condensers in refrigeration systems offers energy savings compared to air condensation or water cooling towers with shell and tube condensers.

- Up to 50% energy savings can be achieved compared to using centrifugal fans. Initial cost savings: cooling tower, condenser, water pump and piping in one piece of equipment

- Low running costs: low condensing temperatures allow the installation of a more compact compressor, which requires less energy

- Low refrigerant charge, minimising costs and environmental impact

- Space savings: floor space savings of up to 50%, compared to comparable air-cooled installations Evaporative condensers reduce water pumping and chemical treatment requirements associated with the refrigerant cooling tower condenser system.

- Substantially lower fan power than air-cooled condenser of comparable capacity.

- Can operate at a lower condensing temperature than the air-cooled condenser.

- No downtime for annual cleaning.

W-Tech condensers

W-tech condensers are all manufactured and assembled according to our ISO 9001 certified quality system. The standard unit is constructed with sheet metal panels type Magnelis® ZM310 to guarantee maximum surface protection comparable empirically to a galvanised sheet metal with over 1000 g/m2 of zinc.

1 The axial suction version uses the fans on top of the machine and is characterised by low power consumption and reduced installation space.

2 The fan-assisted evaporative condensers have higher efficiency and simplified maintenance due to the positioning of the motor and fan.

3 Centrifugal fan evaporative condensers are a classic solution for installations in areas where a defined noise level must be met and refrigerants such as ammonia and freon gas are used. Inlet and outlet silencers can be fitted, further reducing the noise emission of the unit.

4 Low height evaporative condensers with centrifugal fans are the best solution where space is limited, especially in height. It is common to have them with a vertical air intake when the installation is in a well.

CAPX

Our innovative evaporative condenser provides better performance and minimal maintenance. Total cost of ownership is much lower, as well as installation and running costs compared to older generation condensers. The CAPX also allows for longer uptime. It has larger access for easier and safer maintenance and repairs. This condenser is a sustainable solution for industrial refrigeration and other industrial process applications.