When it comes to efficient heat rejection methods, closed circuit coolers have been gaining prominence in the HVAC and industrial process industries. Unlike their open cooling tower counterparts, closed circuit coolers utilize a unique approach, which involves evaporative cooling without any direct contact between the process fluid and ambient air. In this article, we will delve into the intricacies of closed circuit coolers, exploring their design, benefits, and common applications.

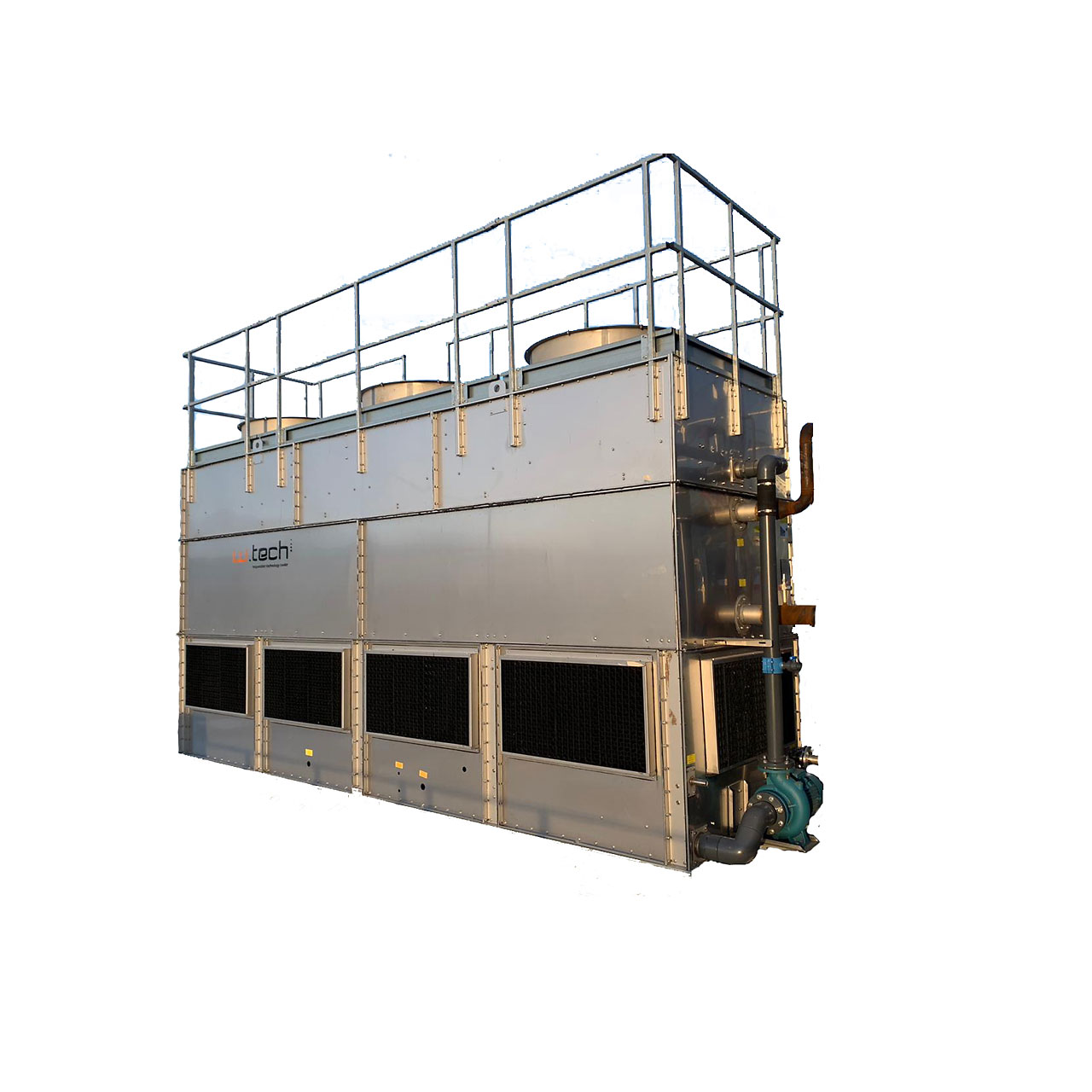

Understanding the Closed Circuit Cooler Design

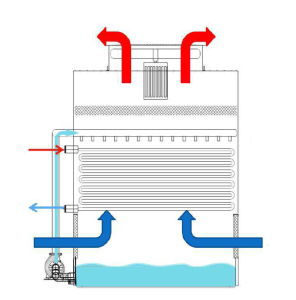

Closed circuit coolers employ a closed loop system that incorporates a coil heat exchanger. This heat exchanger houses the process fluid within, ensuring that it remains isolated from the surrounding environment. A pump is responsible for circulating water over the exterior of the coil bundle, where a fraction of it undergoes evaporation, effectively dissipating heat in the process.

One of the key advantages of this closed loop design is its ability to maintain the process fluid’s purity by keeping it free from airborne particulates. This feature plays a pivotal role in preventing heat exchange surface fouling, thus optimizing system efficiency. Moreover, it reduces the need for frequent maintenance, resulting in lower operating costs. By implementing this “Closed Loop” system, closed circuit coolers simplify the hydraulic loop, especially when compared to systems involving cooling towers and heat exchangers.

Closed Circuit Cooler

Benefits of Closed Circuit Coolers

Closed circuit coolers offer several advantages over alternative cooling methods, such as dry coolers. Here are some of the noteworthy benefits:

Space-Efficient Design

Compared to dry coolers, closed circuit coolers require significantly less space. This compact design makes them a preferred choice, particularly in applications where space is limited.

Reduced Power Consumption

Closed circuit coolers also demand less connected horsepower. This efficiency not only saves energy but also contributes to cost savings in the long run.

Dual-Mode Operation

Many closed circuit coolers have the flexibility to operate as dry coolers under low load or low ambient dry bulb conditions. This dual-mode operation conserves water and eliminates the need for ice management, making them an environmentally conscious choice, especially in colder climates.

Evaporative Closed Circuit Coolers

Common Applications of Closed Circuit Coolers

Closed circuit coolers find a wide range of applications across various industries. Some of the common uses include:

1. Water Source Heat Pumps

Closed circuit coolers are ideal for water source heat pumps, ensuring efficient cooling without compromising the purity of the process fluid.

2. Computer Room and Data Center Cooling

In the world of IT, where temperature control is critical, closed circuit coolers play a vital role in maintaining the optimal environment for data centers and computer rooms.

3. High Efficiency, Low Fouling Chillers, and Heat Exchangers

Industries that rely on high-efficiency equipment benefit from the reliability of closed circuit coolers, which minimize fouling and maximize performance.

4. Critical Chilled Water Applications

For applications where precise temperature control is essential, closed circuit coolers provide a dependable solution.

5. Industrial Process Equipment

Closed circuit coolers are extensively used in industrial processes, ensuring consistent and efficient cooling.

6. Chiller Plant Economizer Applications

In chiller plants, closed circuit coolers can be integrated as economizers, enhancing overall efficiency.

7. Evaporative Cooling with Dry Cooling Capability

With the ability to switch to dry mode during certain conditions, closed circuit coolers offer a versatile cooling solution, combining evaporative and dry cooling methods.

Conclusion

In conclusion, closed circuit coolers have emerged as a reliable and efficient means of heat dissipation through evaporative cooling. Their closed loop design ensures process fluid purity, reduces maintenance, and optimizes system efficiency. With various applications across industries, closed circuit coolers have proven their worth as a versatile and cost-effective cooling solution. When it comes to maintaining temperature control while conserving resources, closed circuit coolers are undoubtedly a compelling choice for both HVAC and industrial processes.