In the creation of this new milestone, we combine what you value most in W-tech evaporators, through forward-looking innovation. The evaporative condenser CAPX offers maximum service life with easy access and impeccable safety. It also stands out for its lower total cost of ownership, including installation, maintenance and operation costs. It should be noted that the CAPX condenser leverages evaporative cooling, making it an inherently sustainable solution for applications in industrial refrigeration and other industrial processes.

Evaporative condenser CAPX

EXTENDED SERVICE LIFE AND IMPECCABLE ANNUAL RELIABILITY

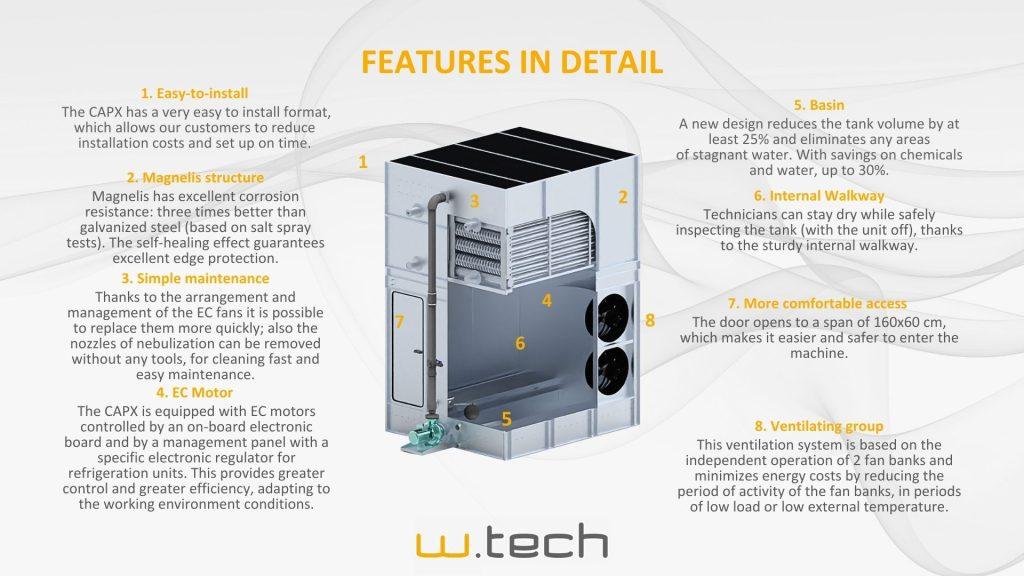

– Maximises reliability and minimises unplanned downtime with EC ventilation system (direct-drive ventilation system with EC motors and axial fans)

– Enjoy peace of mind and uninterrupted operation thanks to multiple fans and motors

– Operates effortlessly in the toughest conditions, thanks to a durable and robust industrial design

– Increase reliability, corrosion resistance and longevity with superior materials, an investment that will save you time and money

EASY AND SECURE ACCESS, ELIMINATING SPACE LIMITATIONS

– The wider access range easily accommodates an individual up to 2 metres tall; a sturdy step and safety handle ensure safe entry and exit

– Access point parallel to the basin, pump and terminal box eliminates the need for platforms or ladders

– Keep yours dry while easily inspecting the tank, thanks to an internal walkway

– Cut maintenance labour costs by 50 per cent and address the risks associated with confined spaces, thanks to a spacious and easy-to-access indoor environment

– We offer industry platforms that can be configured according to OSHA standards to meet your specific needs in the field.

LESSER INSTALLATION COSTS, SAVING 30% IN INSTALLATION COSTS

– Reduce on-site labour requirements and ensure timely commissioning with pre-assembled platform options

– Alignment of the top section with the bottom section takes less than 15 minutes for each module, thanks to the industrial strength of the unit

– Simplify field installation and save time with single-point EC fan wiring

– Saves time and money: no VFD or vibration switches required [3].

50% REDUCTION IN MAINTENANCE COSTS

– Direct drive EC Fan system requires no periodic maintenance

– Easy inspection of the tank, filter and drive components is possible thanks to a robust internal walkway

– The compact, sloping water tank facilitates easy cleaning and improves hygiene

– Savings in chemical and water costs due to 30% less water volume [2].

– Quick and easy inspection of all nozzles, with pre-assembled platform options at an ergonomic working height

– Reduce maintenance costs and maximise uptime with BAC’s independent belt-driven fan system (optional), which facilitates access to all drive components.

GREATER EFFICIENCY, WITH 10 PER CENT LOWER ENERGY CONSUMPTION

– Cut operating costs thanks to highly efficient EC Fan system with variable speed and direct drive

– In many replacement situations, the innovative design could offer higher capacity or lower power consumption, while maintaining the same weight

– Guaranteed energy savings through better control of static pressure in the winter months due to the lower speeds of the EC Fan system.